On Time. On Spec.

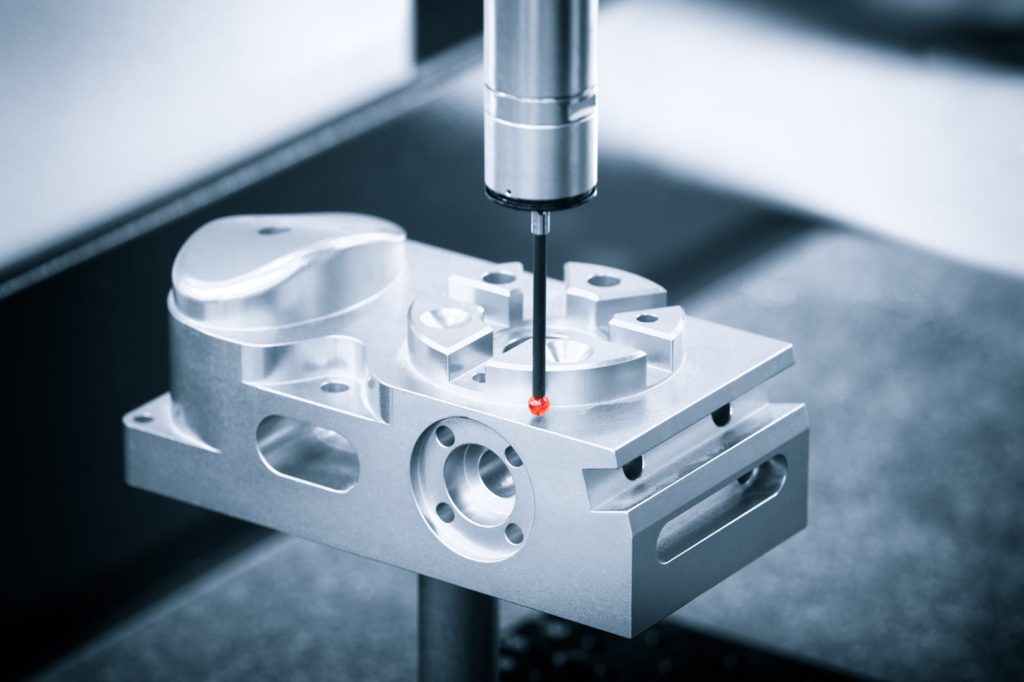

Metrology-driven machining and calibration—parts that fit the first time.

AS9100-compliant quality practices. CNC milling & turning (4th & 5th axis where applicable). Quick-turn prototyping to small-/mid-volume. On-site inspection & first-article documentation.

Critical-industry focus

Blueprint in, proven part out. We machine, measure, and document—tight tolerances, predictable lead times, and AS9100-compliant practices for critical work.

“The first article passed without revision—and every delivery since has been on time and on spec.”

— Jenna R., Manufacturing Engineer (Defense)

Precision

Okuma, Bridgeport & Deckel Maho capability for complex work. Tight tolerances with 4th/5th-axis where applicable.

Reliability

AS9100-compliant workflows, repeatable setups, and SPC checks. Jobs ship when we say—on time, on spec.

Traceability

First-article, in-process, and final inspection with documentation. Lot-level records and calibration protocols on request.